FEMTO SECOND LASER

We have 150 femtosecond ultrafast laser oscillator system in OMAD lab. This Ti:sapphire (Coherent Mira-900) oscillator is pumped by a 10 W green CW diode pumped laser (Coherent Verdi V10). The oscillator emits 800 nm, 150fs pulses at a repetition rate of 76 MHz. The laser has very good stability over long periods of time with slight deviation in power. We routinely use this laser to make microstructures using two photon lithography and terahertz spectroscopy. On coupling these pulses to a photonic crystal fiber (NKT Photonics SCG800), supercontinuum light emission is obtained which is used for measuring coherent white light transmission studies.

Figure 1. Coherent MIRA-900 in OMAD Lab Schematic

We have 150 femtosecond ultrafast laser oscillator system in OMAD lab. This Ti:sapphire (Coherent Mira-900) oscillator is pumped by a 10 W green CW diode pumped laser(Coherent Verdi V10). The oscillator emits 800 nm, 150fs pulses at a repetition rate of 76 MHz. The laser has very good stability over long periods of time with slight deviation in power. We routinely use this laser to make microstructures using two photon lithography and terahertz spectroscopy. On coupling these pulses to a photonic crystal fiber(NKT Photonics SCG800), supercontinuum light emission is obtained which is used for measuring coherent white light transmission studies.

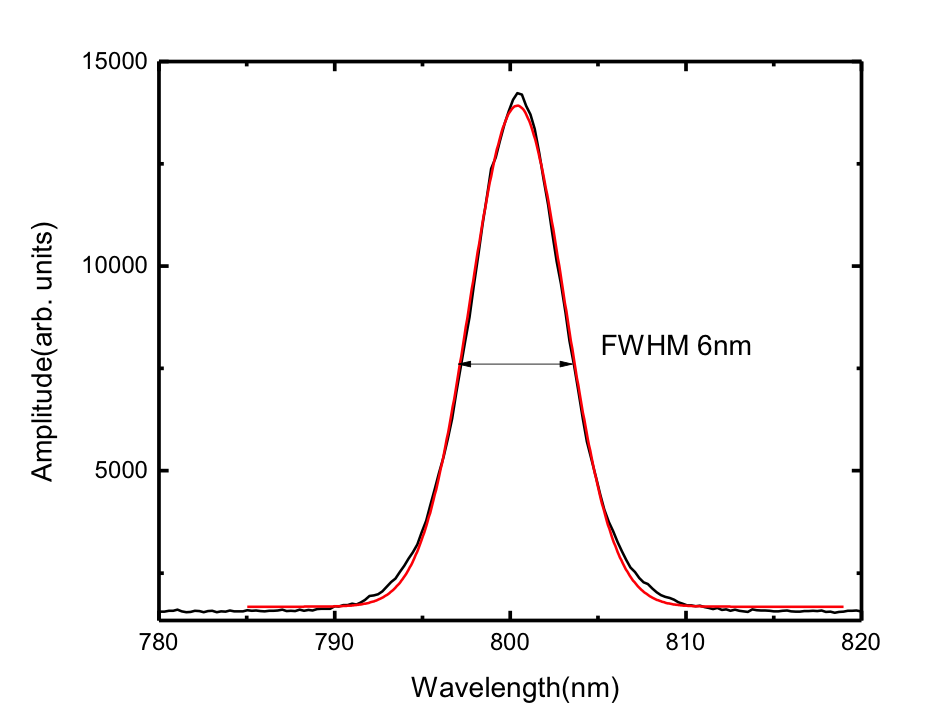

Figure 3. Auto-correlation trace recorded for the Mira-900 pulses using a home-built setup

Figure 4: Typical Mira-900 spectra recorded by OceanOptics HR4000 spectrometer

TWO PHOTON LITHOGRAPHY SYSTEM

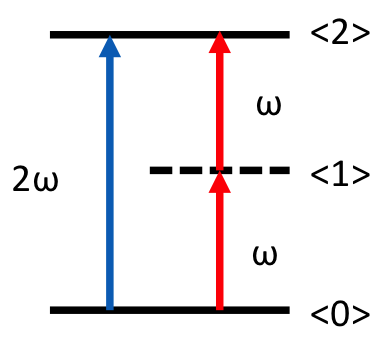

Two photon lithography is the leading technique for making arbitrary 3D structures in polymer resins. The technique relies on the nonlinear absorption of light by monomer molecule leading to cross-linkages, hence leading to polymerisation. In general, the light having energy resonant with the bandgap of the molecule gets absorbed and the material is transparent to light with lesser energy. However, when photons with half the energy of the bandgap are available, as shown in the figure, it is possible to excite the molecule to higher state in two step absorption process via a virtual or real state. This principle is exploited in two photon based lithographic systems.

Figure 1. Possible excitation mechanisms in the two photon setup.

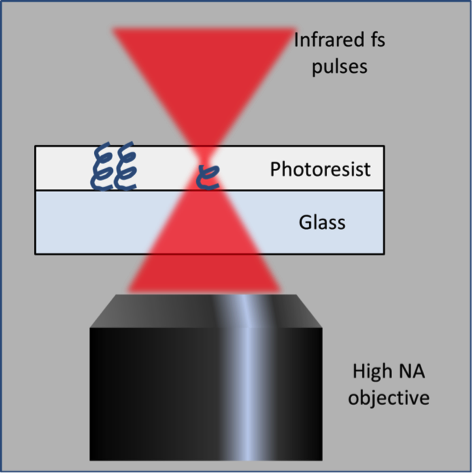

For ultraviolet sensitive monomer resin, infrared femtosecond pulses are employed to induce the two photon absorption which in turn leads to subsequent polarisation. Since the two photon absorption probability is very less compared to one photon case, the light needs to have tremendous intensity. For this reason, the femtosecond pulses which have high peak powers are utilized and they are focused by a microscope objective to achieve higher intensities through space-time focusing. Two photon absorption occurs only at the focal spot of the objective which means that minimum feature of this tool is a voxel(volume pixel) or a spheroid in three dimensions. The movement of this focal spot within the resist allows us to fabricate arbitrary structures depending on the position of the stage. Dosage depends on the the power of the laser and the time duration of irradiation at a particular spot. Dosage also controls the feature size.

Figure 2. High Numerical Aperture objective focuses the infrared femtosecond pulses spatio-temorally in the monomer resin to form polymer linkages.

Important advantages of two photon lithography over UV lithography are :

- Three dimensional resolution is due to local cross-linking at the focal spot of the laser.

- Sub diffraction resolution : The nonlinearity of the process leads to dependence of exposure on the time and power of the incident laser pulse.

- High Penetration Depth is possible due to the choice of non-resonant wavelength which gets absorbed only at the focus. Therefore, it could be used to make structure deep within the photoresist.

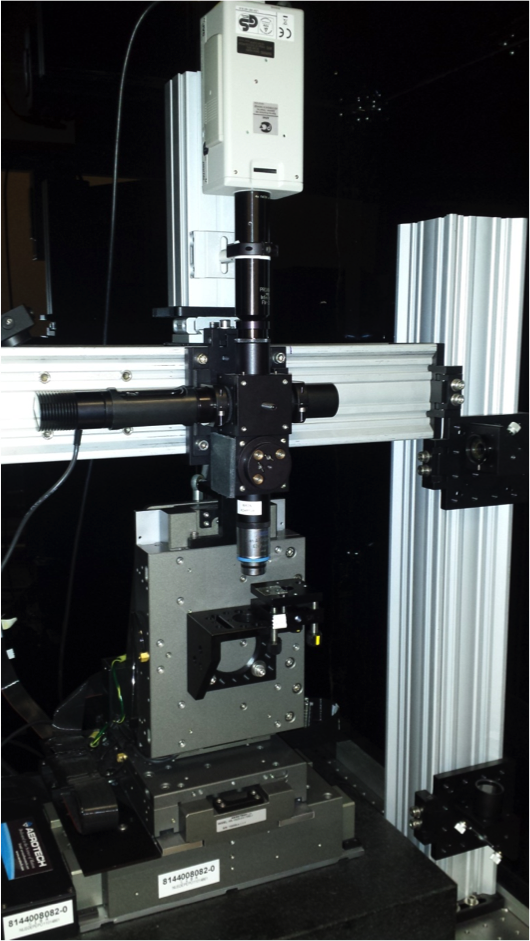

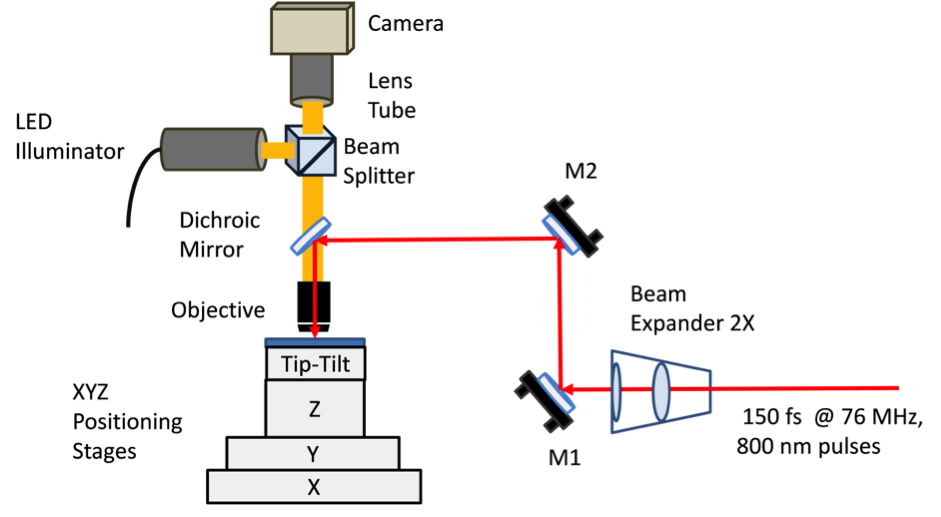

Figure 3. Schematic for OMAD home-built Two Photon Lithography system

The setup consists of a femtosecond oscillator(Coherent MIRA 900) providing 800nm femtosecond pulses of 150 fs duration at 76 MHz repetition rate. These pulses are then isolated from the cavity using a Faraday optical isolator. For controlling the energy of the pulses, we use a polarizer-half-wave plate combination. An acousto-optical modulator is used to generate the first diffraction order beam. This beam is then expanded 10 times by a telescope for ensuring that the back-aperture of the objective is illuminated completely. Then, a periscope is used for steering the beam into custom home made microscope with a high NA objective. The sample is put on a manual tip-tilt stage and 3D stages (Aerotech ABL 1000) to ensure the flatness and movement of the laser spot in three dimensions. We have developed home-built software, Photon Sculptor, for executing programmed exposures to achieve arbitrary structures. Our present capability could be demonstrated using the following structures.